Products

Full Servo Adult Diaper Machine

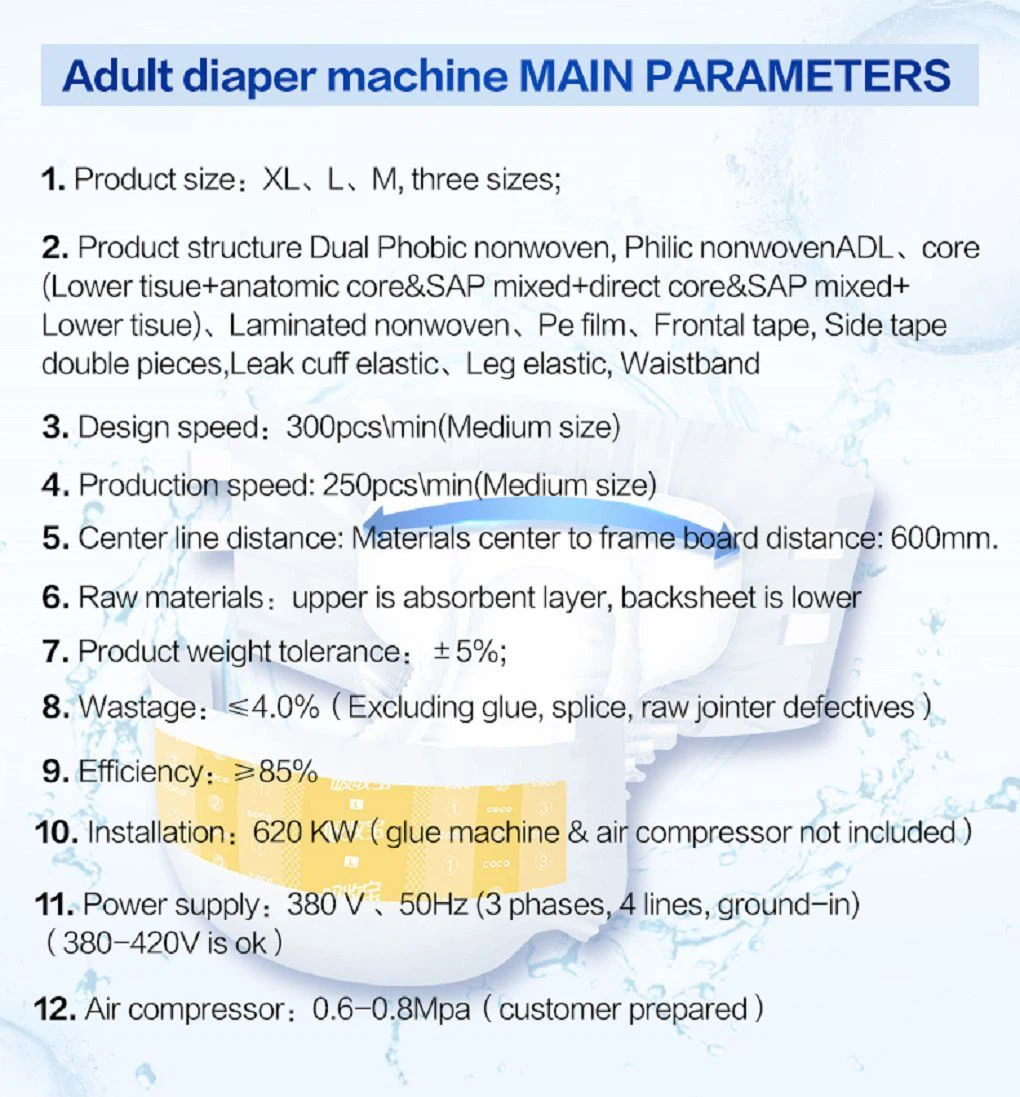

Adult diaper machine

Adult pull up diaper machine

Adult pull up diaper machine drawing

1. Product O-shape die cut, product center folding, with inner and outer auto web guider (17/18), 450mm width(O-shape with chain hoist, easy for change cutter)

2. Pull-ups both end positions checking, auto web guider (19),width 500mm

3. Disposable tape unit, cut and place. Width 12-15mm after slit, passive shaft, manual splice. auto web guider (20),width 150mm, absorbent transfer roller use 5.5KW independent pump, strengthen absorption.

4. Product fold and side end Heat sealing & cut station

5. The pull-ups 90 degree turning.

6. Two rejection exit.

Our patent:

At present, disposable sanitary products, such as diapers and disposable mattresses, are equipped with a fluff pulp added with SAP

A core body, the first mock exam, is formed as a main absorption part. In production, the core structure is molded by a mold and is formed during the molding process.

Sap is added to the, and the corresponding existing equipment is designed and developed specifically, but there are high requirements in the market at the same time

Quantity requirements, such as disposable mattresses for absorption, adult diapers and other products with high absorption requirements, and primary products for isolation

The existing equipment cannot meet the requirements of thin and low absorption products such as sexual mattress products and baby diapers at the same time

Manufacturing of products in two technical directions.

The utility model provides a core with a composite structure

The body forming device comprises a feeding component, in which a base material is arranged

Feeding mechanism; A transmission assembly comprising a transmission module for transmitting a substrate

Transmission line body; And a plurality of component feeding assemblies, which are transmitted along the

The flow direction of components is arranged in turn; Among them, through a number of

The material components are laid on the substrate layer by layer to form the product

The component feeding assembly is used for conveying the finished component to the transmission group

The transmission component drives the substrate to move to the group in turn

At the feeding station of the component feeding assembly, the component feeding assembly

The finished components are laid on the substrate at one time, which is convenient to realize automatic feeding

The utility model can be used to form products and improve the forming efficiency

Convenient, simple structure.

Hot Tags: full servo adult diaper machine, China, manufacturers, factory, price